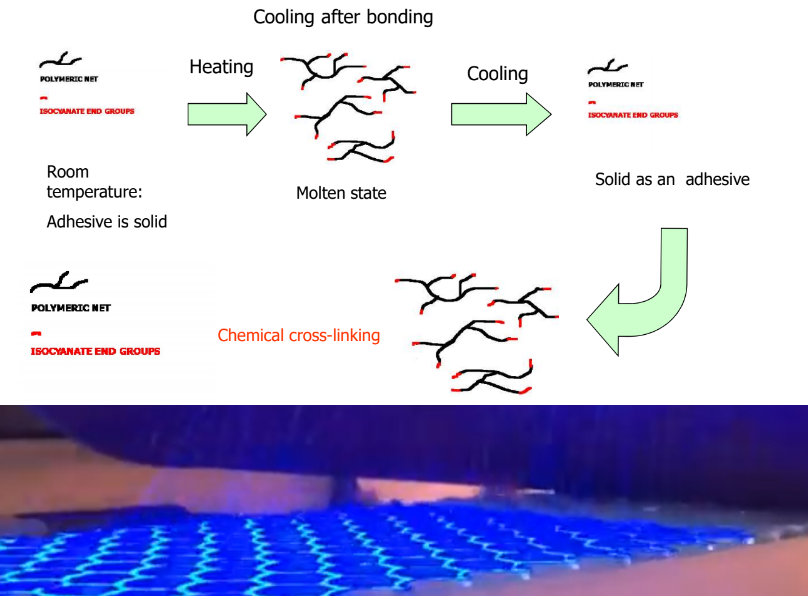

Reactive hot melt adhesives are heated before processing and applied in a molten state. These PUR hot melt adhesives are a successor of traditional thermoplastic hot melt adhesives, mostly based on EVA and Polyolefin polymers. As with traditional hot melt adhesives, initially, cooling results in a purely physical strength build-up, which results in a corresponding initial strength. In the days after chemical cross-linking then takes place through reaction with water molecules which are taken from the glued substrate or air humidity.

Crosslinking

Due to the cross-linking, reactive hotmelt adhesives meet increased requirements with regard to strength, water and heat resistance as well as chemical resistance.

Improved adhesion Strength

The reactive groups in the hotmelt adhesives also have an extremely positive effect on the adhesion spectrum, as the adhesive can additionally form solid (covalent) chemical bonds with suitable reaction partners on the substrate surfaces.

In addition to reactive hot melt adhesives on polyurethane and polyolefin basis in all delivery forms, Intercol also offers a new high-performance adhesive as unfilled- and low emission PUR hot melt adhesive.